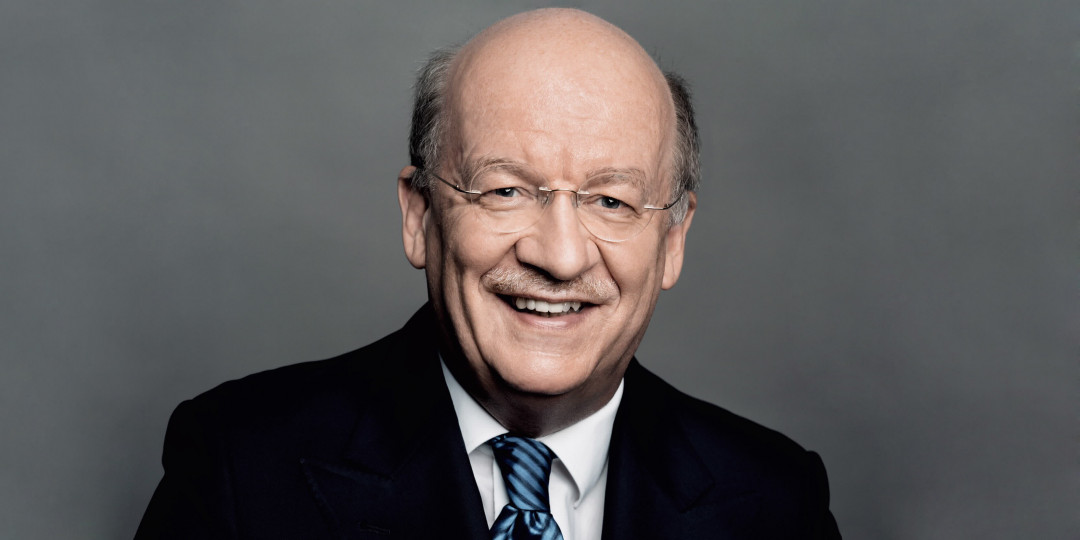

Industrie 4.0 is a firmly established term that continues to aptly describe current challenges and opportunities. That is why the Industrie 4.0 Research Advisory Board and the Industrie 4.0 Platform reject the unnecessary use of "Industrie 5.0". In the interview, Prof. Dr. Wolfgang Wahlster, one of the founding fathers of Industrie 4.0, talks about the current priorities in the further development of Industrie 4.0. Wahlster is a member of the Industrie 4.0 research advisory board, which is coordinated by acatech, and one of the leading figures in artificial intelligence in Europe. He is currently also chief advisor to the management of the German Research Center for Artificial Intelligence (DFKI).

Mr Wahlster, in their joint statement, the Industry 4.0 Research Advisory Board and the Industry 4.0 Platform criticise the use of the term Industry 5.0. What is wrong with developing the term further?

I developed the term in December 2010 during a discussion with Henning Kagermann and Wolf-Dieter Lukas at the acatech project office as a more catchy name for "cyber-physical production systems", which we had previously proposed as a future project in our promoter group of the German government's research union. The idea was that, after the first three industrial revolutions, which can be read about in every book on the history of industry, the introduction of the Internet of Things in factories would now usher in a completely new era of production through a fourth revolution. I then visualised this in a step-by-step diagram, which is now used in various adaptations worldwide in numerous publications to illustrate the four phases of industrial development. The "4.0" was also intended to trigger a connotation with the usual IT designations of system versions, which emphasises the essential importance of software and data for this fourth industrial revolution.

A term undergoes a change in meaning over the course of its use, as any linguist can confirm. Industry 4.0 today encompasses concepts such as digital twins, management shells, generative AI production planning and team robotics, which did not even exist in 2010. This elasticity of the term "Industry 4.0" is an advantage, because when a new industrial revolution begins, not all of its technological, economic and social components are fully known. It is not helpful to proclaim a new industrial revolution after less than 30 years, when it only encompasses a few possible further developments of the core concepts, as these can be naturally incorporated as evolutionary extensions of the term as long as the objectives of Industry 4.0 have not yet been achieved in all dimensions.

The joint statement emphasises not only the current relevance of Industrie 4.0, but also the broad understanding of the concept. In view of the very dynamic technological, economic and institutional development since the concept was introduced at the Hannover Messe 2011: As one of the founding fathers of the term, where do you see current challenges for industry and key areas in the implementation and further development of Industrie 4.0?

We should be confident in the knowledge that, as the world's leading factory equipment supplier, we still have a global advantage with our latest smart factories based on industrial AI. With Industrie 4.0, we have triggered a huge wave of innovation – for the first time in many years, from Germany. The term Industrie 4.0 is now not only established in Europe, but is also a conceptual export hit from Germany in the USA, Japan and China, and has played a central role at all major industrial trade fairs since the Hannover Messe 2011.

A key challenge is to maintain this momentum and to drive forward the fourth industrial revolution worldwide, for example in India and Africa. Ultimately, the success of the first three industrial revolutions is also due to the worldwide spread of the respective waves of innovation, albeit with a time lag. I would like to illustrate this with two specific examples.

Professor Marik from the CIIRC in Prague published a much-cited book on "Prumysl 4.0" (Czech for Industry 4.0) as early as 2016. In 2019, one of the largest research projects was launched with a funding amount of EUR 50 million for six and a half years from the EU's Teaming programme to establish a distributed centre of excellence in the Czech Republic with scientific and technical start-up assistance from Germany. The goal of quickly bringing both industrialised countries up to the same level, despite the time advantage of institutes such as the DFKI with its world's first smart factory, was quickly achieved, so that the two important industrialised nations could then successfully cooperate at eye level in research and industrial transfer.

It is very encouraging that, long after Germany provided start-up assistance to the Czech Republic, Prague is now providing start-up assistance to Jaipur (India) to teach the basic technologies for Industry 4.0, such as AI, robotics and cyber-physical systems, at a new institute of the private NIMS University, which is to be opened in 2024. The new institute is modelled on the CIIRC in Prague and, as the Marik Institute, bears the name of the pioneer of Industry 4.0 in the Czech Republic. This has created a "scientific-technical supply chain" from Germany, the country of origin of Industry 4.0, via the Czech Republic to India, which is of great importance in view of the need for skilled workers to further implement Industry 4.0 in Germany.

In Kigali (Rwanda, Africa), a Centre for the Fourth Industrial Revolution has been in existence since this year, which will hold the "Global AI Summit on Africa" in October 2024 to show how AI is further advancing the implementation of Industry 4.0. An experienced researcher from the DFKI, which serves as a model for the C4IR, will now work at the centre for two years as a "development aid worker".

With the publication of the joint statement, the speakers of the research advisory board and the chairman of the steering committee of the Industrie 4.0 platform emphasised that companies, and in particular SMEs, are now aware of the importance of Industrie 4.0. What key opportunities or possibilities do you see for industrial companies, but also for society, in the course of further orientation towards Industrie 4.0?

The even broader applicability and availability of artificial intelligence technologies will drastically simplify the introduction of Industry 4.0 and the migration of existing systems. At present, complexity hurdles and the lack of highly specialised experts with up-to-date and interdisciplinary know-how in computer science, mechanical engineering, production technology and ergonomics are still obstacles for many companies, especially SMEs, when it comes to introducing Industry 4.0. These barriers can be overcome, for example, with the latest generation of collaborative robots, which no longer need to be programmed in detail because they can generate the program code with machine learning and large language and action models (LxM technologies) in a partially autonomous manner.

However, there is still a considerable need for research in the area of emotional and social intelligence in interaction with robots in order to transfer teamwork, as it is common today in many factories among skilled workers, to hybrid teams of collaborating, mobile robots and humans, each of whom contributes different skills to solve a production task. First of all, it still needs to be clarified how a dynamic and fair distribution of tasks in the team can be achieved in a situation-adaptive manner. The goal of achieving the "team spirit" familiar from social and occupational psychology, with mutual support from all actors through transparent and multimodal communication for all members of a hybrid team, is also very ambitious.