It causes cable breaks in mobile phones and defects in aircraft turbines: the Kirkendall effect. This ensures that composite materials become porous and unstable. In order to better control these defects, Prof. Dr.-Ing. Bettina Camin wants to find out how porosity develops. As the first scientist to do so, she is observing the voids in the material in real time as they occur in a research project at the University of Applied Sciences in Bremerhaven. Recently, she left her laboratory to conduct experiments at the European Synchrotron Radiation Facility (ESRF) in Grenoble. The project is funded by the German Research Foundation (DFG).

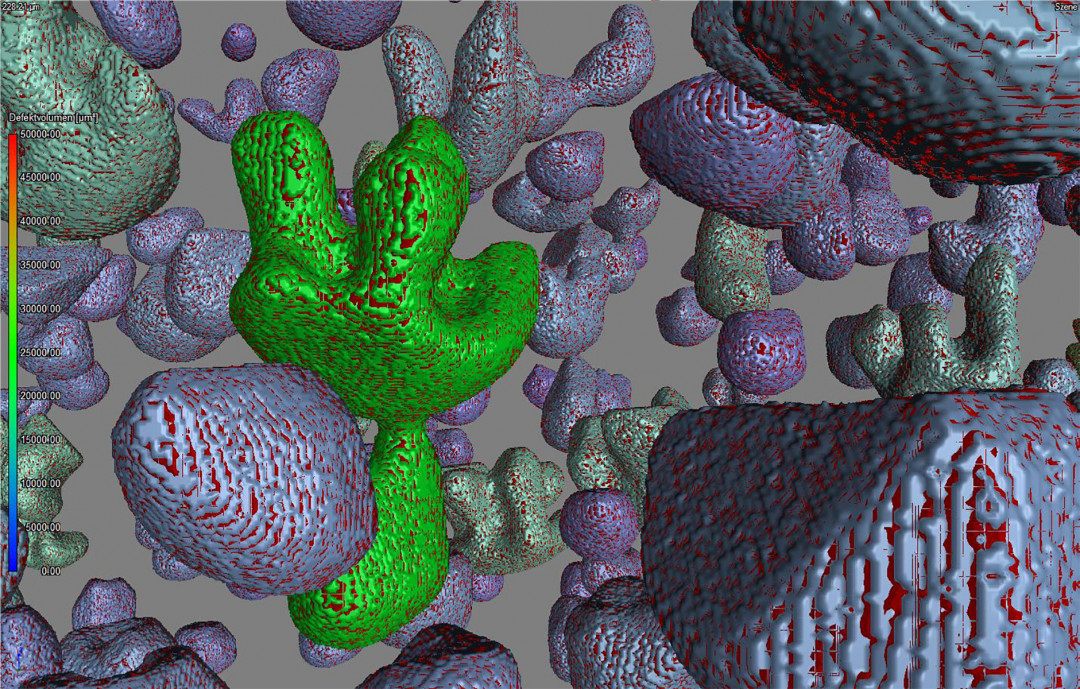

The Kirkendall effect can be observed wherever two different materials come into contact with each other and are exposed to high temperatures. This results in diffusion currents, in which atoms of the materials migrate to the other side. However, this does not happen evenly. ‘For example, if we take pure nickel on one side and a nickel alloy with aluminium on the other, pure nickel migrates much more slowly than aluminium. This initially creates tiny voids at the point where the materials meet. These become larger over time until the material is so porous that it fails,’ says Prof. Camin. The interesting thing is that although this effect has already been well researched, it is currently not possible to predict exactly how these holes develop. Their shape can also vary greatly: ‘At the beginning, the pores are spherical, but over time they change and then look like a drop, anchor or a branched cactus, for example.’

To find out why this is the case, Prof. Camin's research team is looking at the formation of pores in real time. To do this, they are using a technique known as synchrotron X-ray tomography. This method allows structures to be visualised in high resolution in 3D. The material to be examined is heated to up to 1,300 °C. This means that the first pores appear after just 24 hours. ‘No research group has done this before. We hope that this will enable us to make a statement about how the number and geometry of the pores develop under certain conditions. In practice, this would make it easier to control the defects,’ says Prof. Camin.

Some of the complex experiments were not carried out in the university laboratories. Prof. Camin successfully applied for two days of research time at the European Synchrotron Radiation Facility (ESRF) in Grenoble. This is a large multinational research facility whose measuring stations can be used by research groups from public institutes and private companies. ‘Our question was the time, temperature and crystallographic orientation-dependent damage development in a composite of pure nickel and a nickel-based superalloy, as used in turbines,’ says the professor. Since the demand for research time is very high, it is only rarely approved. In order to use the time as efficiently as possible, the professor travelled to Grenoble with her four student assistants. ‘I have an incredibly good group of students who work very independently and with great dedication. That's why we were able to split up for the experiments at the ESRF and work on different devices at the same time. I was even asked how great the students are,’ says Prof. Camin.

The evaluation of the measurement data from the experiments in Grenoble will take some time: the team brought around 20 terabytes of data back to Bremerhaven. ‘We will certainly need six to twelve months to evaluate everything. From a first overview, the result so far is that the three varied parameters actually each have an influence on the damage to the material. We were also able to carry out an experiment that showed us that we can achieve the goal of our project,’ says Prof. Bettina Camin.

The project ‘Kirkendall porosity in diffusion couples: investigation of formation and morphologically unstable growth using synchrotron X-ray tomography and phase field simulation’ is a collaborative project with the Ruhr University Bochum.