The UltraPLAS coating developed by Fraunhofer researchers has proven to be a groundbreaking solution for the challenges of primary shaping processes. This advanced release and easy-to-clean coating is applied as a gradient layer using a cold plasma process and is suitable for materials such as tool steel, stainless steel and aluminium. Thanks to its special physical properties, UltraPLAS enables the perfect reproduction of surfaces ranging from nanoscale to mirror-like. The application is considered highly economical due to a reduction in the number of post-processing steps and the elimination of external release agents.

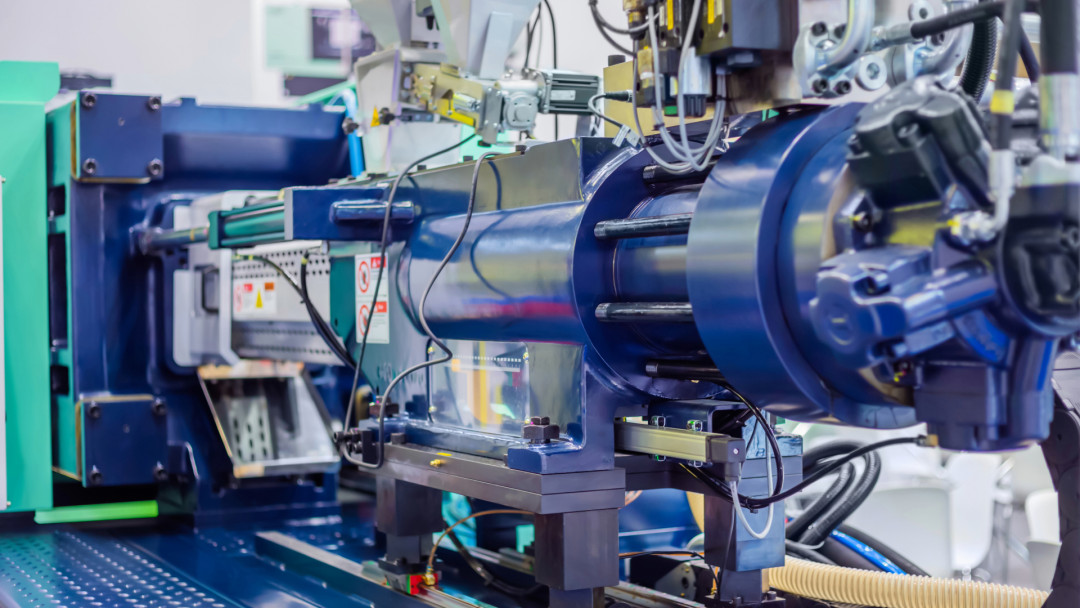

How can high-quality and demanding tool surfaces be coated in such a way that production is improved and cleaning processes are significantly delayed or simplified? This question was investigated by researchers at the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research IFAM together with partners in the projects ‘GlossyCast’ and ‘UltraTrenn’, which were funded by the German Federation of Industrial Research Associations (IGF). The aim of the research projects was to reduce the demoulding forces and the formation of deposits on the mould surfaces, while at the same time permanently withstanding the specific stresses of zinc die casting and plastic injection moulding.

The injection moulding of technical plastic parts in particular requires solutions to reduce demoulding forces and the formation of deposits. This applies especially to the production of components with high-gloss surfaces or with highly defined microstructures, such as plastic lenses, decorative trims or highly dimensionally stable connectors. In the same way, deposits, release agents and lubricants prevent the production of high-quality, shiny metal surfaces in zinc die casting. This results in considerable costs for reworking. Regardless of this, the application of release agents alone can account for around 20 per cent of the cycle time, so there is considerable potential for savings if release agents can be dispensed with.

In order to fulfil the requirement profile within the projects, that the release coating can produce ultra-smooth, optical surfaces (Ra < 25 nm), the coating itself must be smooth and structureless. To fulfil these criteria, the cold plasma process, the so-called PE-CVD process (plasma enhanced chemical vapour deposition), was used. By creating a gradient layer, this process enables excellent adhesion to the product body on the one hand, and very good non-stick properties with excellent physical characteristics on the other.

The coating produced in this way is characterised, for example, by a high modulus of elasticity (28 – 32 GPa) and a high density (1.5 g/cm³). This results in a Mohs hardness of 5.5, which is on a par with glass or enamel. Another characteristic is that, as a non-stick coating, it also has a low surface energy (< 28 mN/m) with low polarity (< 1.5 mN/m).

This behaviour is supported by the fact that the Fraunhofer researchers have succeeded in producing the UltraPLAS® coating with a particularly low layer thickness of less than 100 nm. This had even proved necessary in the GlossyCast project in order to provide a good non-stick effect. In addition, the thin, structureless layers allow both nanoscale surface structures, e.g. for the nanoimprint process, and mirror-like surfaces to be perfectly reproduced.

Sustainable quality and economical production guaranteed

Extensive practical tests conducted as part of the projects at various industrial companies have shown that the demoulding forces and coating formation are reduced in the area of injection moulding. It has also been shown that the total demoulding forces decrease as a result of the reduction in adhesion forces. Consequently, the demoulding temperature can be increased and the friction component reduced.

In contrast to the current state of the art, the coating can be removed effectively and gently using plasma technology, so that if necessary a new coating can be applied several times without any loss of quality. This is particularly interesting for high-gloss tool surfaces, as it means that the expensive polishing work or ultra-precision machining can be dispensed with.

It has also been shown that the direct casting of high-quality zinc die-cast surfaces can significantly increase cost-effectiveness. The significant improvement in the surface quality of the castings means that cost- and time-intensive mechanical finishing steps such as blasting, grinding and polishing can be simplified or even avoided altogether. In addition, the individual process steps of the galvanic surface coating can be shortened or reduced. The development of this durable separating layer for zinc die casting represents a significant advance in casting technology. The ability to dispense with the use of separating agents opens up new potential for improving casting quality, reducing production costs and making production more environmentally friendly.

Since the zinc castings were produced without separating agents, the pre-treatment time for galvanisation is reduced and material consumption is lowered. The manufactured components have the desired roughness. Due to the smoother surface, the bright copper coating can be dispensed with, which leads to savings in materials, time and waste water. The reduction of the layer thickness of copper (cyanide) and bright nickel by 50 per cent each led to further savings in materials and time.

The development of UltraPLAS was preceded by the PLASLON non-stick coating, which is characterised by a high hardness (Mohs hardness 4.5 - 5.5) and excellent temperature resistance up to 230°C. This property profile has made PLASLON a popular, PFAS-free easy-to-clean coating for cookware. Through continuous innovation and the development of products such as UltraPLAS and PLASLON, our institute is making a significant contribution to improving production processes and promoting sustainability in industry.