Researchers at TUD Dresden University of Technology are developing innovative production processes for the reuse and recycling of metal components in the project "2nd Life Metal Components: A Pathfinding Project for Upcycling."

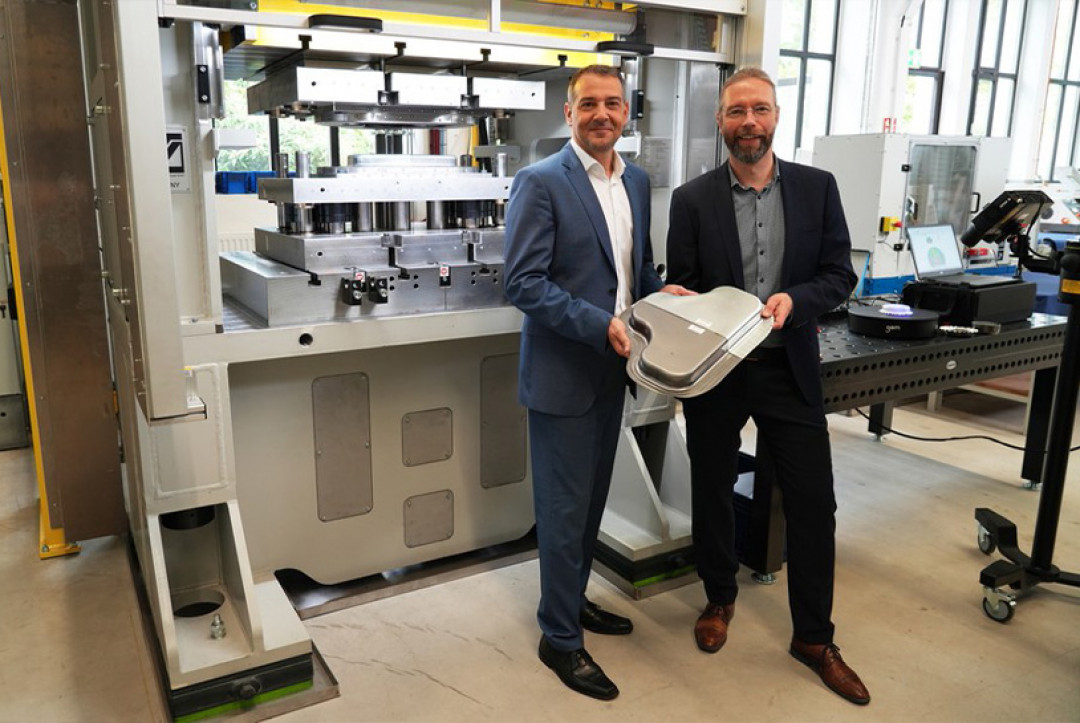

The project will run for eight years and is headed by Prof. Alexander Brosius and Prof. Andrés Fabián Lasagni from the Institute of Manufacturing Science and Engineering. It is funded by the Werner Siemens Foundation with a total of EUR 13 million. The project will open up a broad field of research for a team of 25 people.

As demand for metals in industrialized nations increases, anthropogenic stocks are also growing continuously. This means that more and more metals are remaining locked-in in infrastructure and buildings over prolonged periods of time. Conventional recycling methods, in particular energy-intensive melting, are no longer justifiable due to the scarcity of resources.

Urban mining: Reusing existing raw material

The "2nd Life Metal Components" project aims to avoid these processes by directly reusing existing metal parts through upcycling and manufacturing new products from them. Reusing existing raw material is known as urban mining. These processes allow for a significant reduction in energy consumption and the conservation of valuable resources. "Our approach enables us to potentially save up to 90 percent of the energy that would normally be required," emphasizes Prof. Brosius. "By sustainably reusing metals, this project will set new standards in urban mining."

Laser-based functionalization is key technology

The project uses laser-based technologies to improve the properties of the recycled metals and to produce tailored blanks with specific properties for defined applications. This innovative approach aims to improve ecological and economic efficiency in sectors such as the automotive industry, to foster circular economy, and to support sustainability goals.

"Laser-based functionalization is another key to the success of this project," explains Prof. Lasagni. "It enables us to characterize both the surface and volume properties of the metals, to precisely fine-tune them to prepare them for being reused, and to improve their properties for new applications in a targeted manner."

Featured photo: Institut für Fertigungstechnik