The two-day Metal Expo witnessed the foundry industry representatives discussing the latest solutions and the future of heavy industry. Over 200 companies from 22 countries presented cutting-edge technologies and machines for the foundry industry. Ecology and Polish sector transformation were among the Targi Kielce Industrial Autumn” highlights.

The future of the industry - business talks and meetings at the Targi Kielce Industrial Autumn

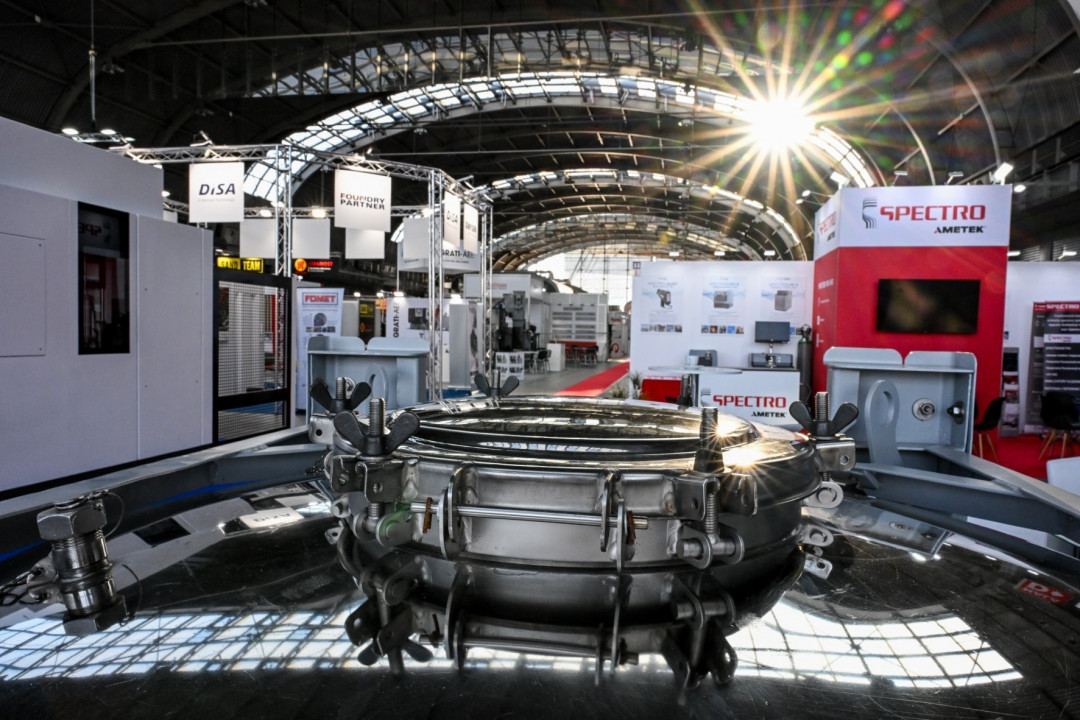

The METAL Expo and its accompanying trade shows: Heat Treatment, Aluminium & Nonfermet, Control-Tech and Recycling have attracted the most prominent companies from the foundry and heavy industry to Kielce for years. This year, Targi Kielce hosted over 200 companies, including such brands as: DISA, Magaldi, Agrati, Frech Polska, Metals Minerals, Motul Baraldi, Kanthal, Mead Formi, RTD Group, Gunther Polska, Inductotherm Europe, Pyrotek, Heraeus, MTR IZO, Enimetal, Metals Minerals, TPE Engineering. These exhibitors’ presence proves the event’s importance; Targi Kielce show is ranked third largest convention of this type in Europe, after the largest GIFA Expo organised in Dusseldorf and Euroguss in Nuremberg. – Accessibility, professionalism and modernity are the three words I associate with the Metal Expo. Our presence in Kielce allows us to reach 40-50 large clients in Poland during the two-day show, something that would typically take us half a year or a year. This shows that the event still has a future – Przemysław Czapla, President of Eurocast Industries, said during the Expo. Thomas Fritsch, CEO of Foundry Planet, was also happy to be present in Kielce; he also emphasised the 20-year cooperation, recalling his beginnings and first visits to Targi Kielce. – The Metal Expo is ideal for industry representatives from this part of Europe. METAL is an essential place on the map of Europe in the context of this industry. The media I represent always try to be where the companies, the best products and industry experts mark their presence. Hence our presence at Targi Kielce – added Thomas Fritsch.

Energy transformation marks the future of foundry business

The Foundry Goes Green seminar was again held within the scope of the Expo; the consecutive Seminar unveiling was devoted to ecology and energy saving in a broadly defined modern foundry. Industry 4.0 and clean air technologies, as well as the cutting-edge heat treatment of metals, are in abundance at the congress. Foundry is an energy-intensive industry with high CO2 emissions; therefore, high energy prices and penalties for environmental pollution force this sector to change. The search for new technologies and, of course, savings is a must. – Poland’s electricity prices are some of the highest in Europe. In June 2024, 810 kg of CO2 was emitted to generate 1 MWh of energy in Poland. For comparison, in Germany - 310 kg, France - only 20 kg – Andrzej Ładysz and Adrian Jonczyk from ABAS Business Solutions Poland said during the Foundry Goes Green seminar. The presenters explained the key aspects of iron foundries' carbon footprint: high process emissions, energy-intensive input materials, electricity and heat, and regulations and initiatives.

Foundry crisis

The foundry industry has been struggling with numerous challenges in recent years, which can be refered to as a crisis. The challenging situations stems from the rising costs of energy, raw materials and the pressure related to ecological transformation, to name a few The requirements for CO2 emissions reduction and growing expectations for sustainable production are putting additional strain on foundries. These problems are particularly acute in Europe, where production costs are higher than in other regions, and as a result, some companies are closing down or moving production to cheaper countries. – Founders are tough people and they will undoubtedly cope even in times of crisis affecting the foundry industry – Ryszard Kielczyk, member of the Board of the Technical Association of Polish Foundrymen at the opening of the Industrial Autumn in Targi Kielce.

New technologies in the non-destructive testing sector

Industrial Measurement Technology and Non-Destructive Testing (NDT) play critical roles in the quality and safety of production processes. Advanced technologies such as ultrasound, radiography, thermography and eddy currents, make it possible to detect material and structural defects without damaging the tested objects. NDT is widely used in automotive, aviation, energy and construction industries, enabling precise inspection of components, which translates into longer life and greater safety of structures and products. Control-Tech is Poland’s most important event presenting the latest measuring instruments and machines. The wide and diversified range of producers was complemented by industry seminars and lectures that featured top specialists. The two-day Expo showcased the latest technologies in specialised measurements, analytical equipment, materials testing, measuring instruments and components for measuring and testing.

More news can be found at www.targikielce.pl/metal website or on Linkedin: https://www.linkedin.com/showcase/metal-trade-fair/. Follow us!