Whether in the automotive sector or in production: simulations and digital twins are indispensable for many companies. Because highly dynamic processes often cannot be satisfactorily modelled using conventional software, researchers at the Fraunhofer Institute for Industrial Mathematics ITWM have developed a solution with the tool MESHFREE that works without a rigid computational grid and is able to simulate complex processes with great time savings and thus cost-effectively. They were awarded the Joseph von Fraunhofer Prize 2024 for this.

Rigid specifications rarely fit agile processes – and what applies to organisations also applies to simulation methods. If complex processes such as aquaplaning or metal cutting are to be modelled virtually, not all component movements can be predicted in advance and incorporated into a suitable computational grid, as is usually the case for simulations.

MESHFREE replaces real-world testing

A research group at the Fraunhofer ITWM faced this challenge over 20 years ago. "Our very first task in the project team was to simulate the deployment of an airbag during a vehicle crash," reports Dr Jörg Kuhnert, who was already part of the group at the time. "At that time, there was no way to quickly check the safety of new developments in this area other than by conducting real, cost-intensive crash tests." The more objects that move and interact with each other in a situation, the more difficult it is to reliably depict them with classic simulation methods at a reasonable cost.

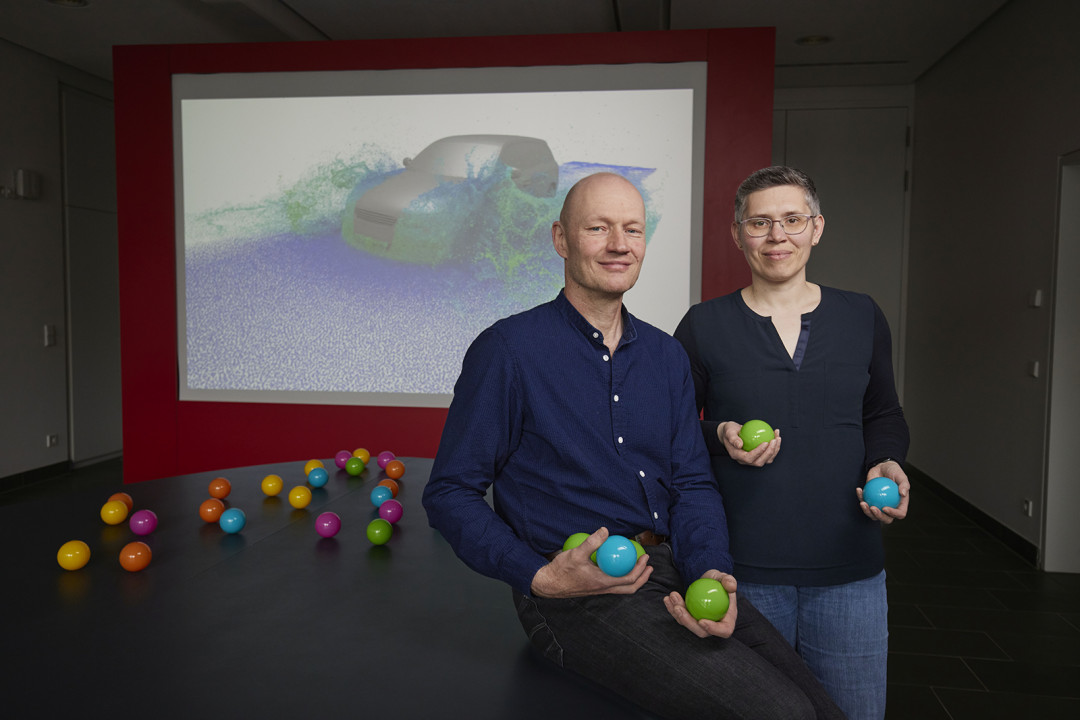

Based on Jörg Kuhnert's doctoral thesis, the team – which has also been working with Dr Isabel Michel since 2012 on the topic of free-jet turbines – developed the innovative mesh-free approach. This makes it possible, in some cases for the first time, to show particularly complex and dynamic situations in the simulation. All the research results achieved since then have been incorporated into the MESHFREE software tool. The result is a simulation tool with a unique selling point: no other simulation tool in the world makes the Generalised Finite Difference Method (GFDM) industrially usable.

Flexible method for dynamic processes

The finite element method is traditionally used for simulations: engineers construct a grid mesh to suit the respective geometry and use it to calculate the changes in each individual element. Even setting up the grid structure is very time-consuming; it also has to be constantly adjusted during the simulation. In contrast, the MESHFREE software combines the Generalised Finite Difference Method for solving the conservation equations for mass, momentum and energy with efficient algorithms for solving linear systems of equations, which were co-developed by the Fraunhofer Institute for Algorithms and Scientific Computing SCAI – a huge advantage, because the numerical point cloud used is able to adapt flexibly to moving geometries. This eliminates the need for time-consuming corrections to the computational grid. Dr Jörg Kuhnert and Dr Isabel Michel received the 2024 Joseph von Fraunhofer Prize for their development, which can replace real-world testing.

From automotive to process engineering – and beyond

The award-winning method can be used for a wide range of applications. One current focus is the automotive sector: in addition to airbag simulation, the researchers have so far been able to support their industrial partners with modelling water crossings or the behaviour of vehicles on sand or gravel, among other things. In process engineering, MESHFREE helped companies to optimise the process parameters for processing glass melts and manufacturing plastic parts.

In principle, the method can be used wherever measurements or experiments are to be replaced or are difficult or impossible to carry out. Isabel Michel summarises: "We are not limited to the classic applications of numerical flow mechanics. MESHFREE can do much more: the tool is deliberately kept generic." The software therefore has great potential to save costs, time and materials in many other fields of application in the future.

Joseph von Fraunhofer Prize

Since 1978, the Fraunhofer-Gesellschaft has been awarding the Joseph von Fraunhofer Prize to its employees for outstanding scientific achievements in solving application-oriented problems. This year, three prizes of €50,000 each were awarded to groups of researchers from different institutes.