The industry-oriented research institute INNOVENT is launching an innovative user project (‘INNAP’) in November on the topic of ‘Laser structuring for hybrid injection moulding’.

The project is primarily aimed at companies that manufacture products using metal-plastic hybrid injection moulding or that produce metal inserts for hybrid products and are looking for efficient, automated methods of surface treatment without the use of chemicals. Companies interested in laser surface treatment of metal materials can register to participate in this joint project.

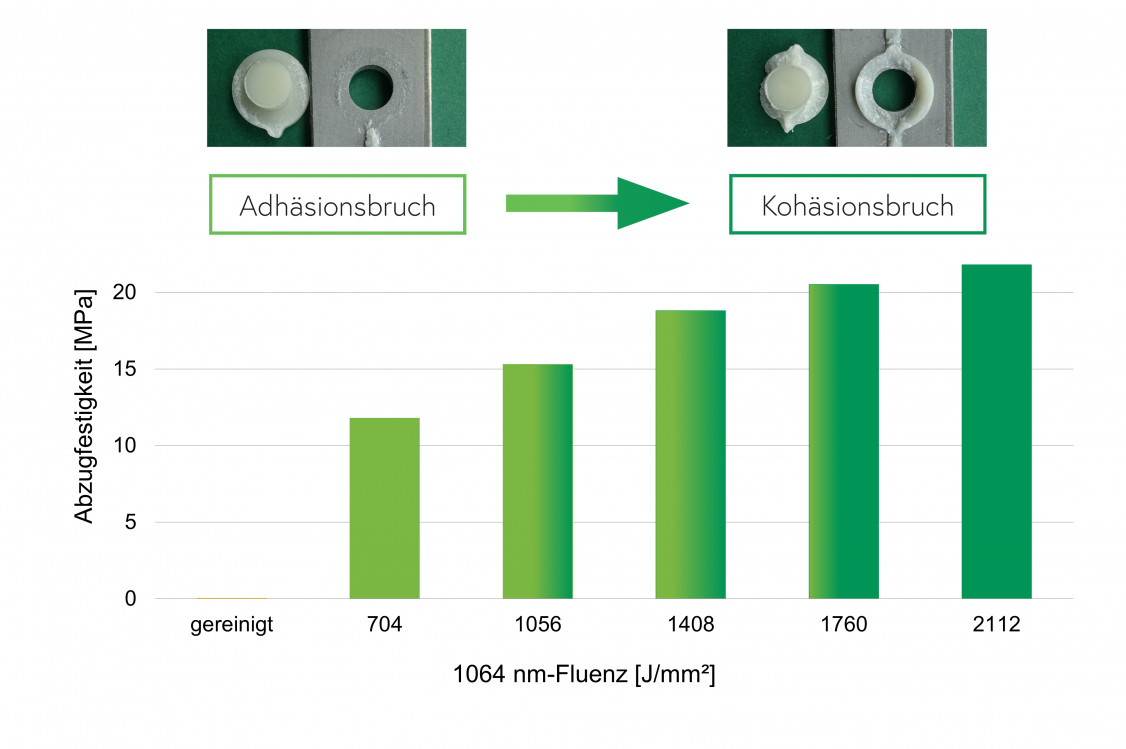

In metal-plastic hybrid injection moulding, polymeric adhesives are commonly used to bond plastics firmly or tightly to a metal insert. As current development work has shown, particularly high levels of adhesion can be achieved by suitable laser microstructuring of metallic composite surfaces. The prospect of being able to dispense entirely with chemicals for surface pretreatment in the case of solid hybrid composites, as well as the potential applicability for a wide range of metal-plastic combinations, are advantages that speak in favour of a broad introduction of laser surface treatment in hybridisation technology.

However, there is still a lack of practical processing and provision of existing knowledge from research projects and preliminary developments that enable a reliable transfer to typical industrial tasks.

Therefore, the industry-oriented research institute INNOVENT is planning a new innovative user project (‘INNAP’) to make the know-how gained so far available to as many industrial users as possible and at the same time to develop a broad database on important technological aspects of practical implementation.

Companies interested in innovative hybrid technologies are invited to participate in the INNAP ‘Laser structuring for hybrid injection moulding’; the project will start in November 2024. The companies that participate in the project will thus have an economically attractive and time-saving opportunity to get to know laser structuring in more detail and to investigate material combinations of their own choice.

The aim of this project is to support interested companies with the laser treatment know-how already available at INNOVENT and the institute's technical equipment and facilities. From practical test series tailored to the specific topics of the participants, statements can be derived on the advantages and potential possibilities of laser surface treatments in the company.

The realisation of the project in the form of a joint project with individual selection of the materials to be investigated offers the opportunity to obtain extensive information on important issues of laser surface treatment in manufacturing processes of interest in a cost-effective manner and with a low level of personnel and technical resources, such as

- Assessment of the advantages and possibilities of laser treatment for specific production tasks

- Feasibility assessment and prospects of success of laser structuring for typical user materials and derivation of constructive requirements

- Assessment of the technological relevance from test series with technologically representative parameter variants of the laser treatment

- Comparison of results with further metal materials introduced by other participants

The services provided by INNOVENT in the project include exploratory investigations into the adhesion-enhancing effectiveness of surface structuring by laser for agreed practice-relevant parameter and structure variants on representative model composites for a metal material freely selectable by the respective participant, with the following sub-steps:

- Carrying out the laser structuring according to the agreed parameter variants and microscopic presentation of the results

- Production of injection moulded model composites

- Composite testing and presentation of the results

- A time frame of four months is planned for the processing of this joint project.

Detailed information on the project form as well as on the content and organisational planning of the project and the registration documents can be found on the INNOVENT website.

Registration for this innovative user project can be done using the following form.