A new multi-chamber system for aqueous ultrasonic cleaning at the Fraunhofer FEP will in future offer flexible cleaning possibilities for industrial component cleaning. This system complements the LinTR learning laboratory, which was developed under the direction of the Fraunhofer FEP together with the Fraunhofer IPA, IWS and IVV Dresden. The learning laboratory offers a comprehensive, modular training concept for industrial parts cleaning for a wide range of requirements and, for the first time, the opportunity to train complex cleaning processes in an extended laboratory environment.

The proverbial ‘sand in the works’ can bring entire systems to a standstill. Often, even the smallest particle contamination or film-like residual dirt in process chains is enough to cause functional limitations or even damage to entire systems on assemblies.

More and more users and process developers are therefore aware that cleanliness requirements must be met along the entire process chain. The cleanliness of the production environment and any necessary cleaning processes are therefore crucial to achieving the quality requirements of a component to be produced. Cleaning processes are therefore of crucial importance for quality. In addition, there are many dependencies between the process steps, preliminary and follow-up processes, which can also have complex influences on the cleanliness of the entire process chain.

A great deal of theoretical knowledge can currently be learned about cleaning processes and quality assurance, and the practical handling of cleaning technology and measuring and testing equipment. However, there has been no way to train in the mastery of complex process chains in relation to parts cleanliness. A new learning laboratory for industrial parts cleaning – LinTR – is now closing this gap.

Funded by the Fraunhofer Academy, the Fraunhofer IPA, the Fraunhofer IVV Dresden and the Fraunhofer IWS are working under the leadership of the Fraunhofer FEP on the design and implementation of the expanded training opportunities. These are not only intended to include the upgrading of technical possibilities, but also to offer a modular, flexible concept and cooperating learning locations.

The learning units of the LinTR learning laboratory are not to be offered in a theoretical sequence, e.g. depending on the lecturer, learning location or topic. The new methodological-didactic concept organises all learning units according to the process chain and offers the appropriate practical training units. This enables participants to understand the technical and logistical relationships at the interfaces of the process chain. In addition, the fundamental importance of interdisciplinary communication for ensuring component cleanliness at all points in the process chain is conveyed, which in many cases uncovers previously unrecognised weak points and leads to simple solutions.

In order to be able to respond to the different time constraints of future learners, a modular concept has been developed that can be flexibly designed to offer a three-day compact seminar or a qualification programme that can be completed alongside work.

For the training of practical skills, laboratories are available at all four project partners, including a laser laboratory at the Fraunhofer Institute for Material and Beam Technology IWS in Dresden. The Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart offers special laboratories on the topics of clean rooms and particle cleanliness. The simulation and practical implementation of spray cleaning are available in the laboratories of the Fraunhofer IVV Dresden, among others. Depending on the scope, live video conferencing or direct on-site use is offered.

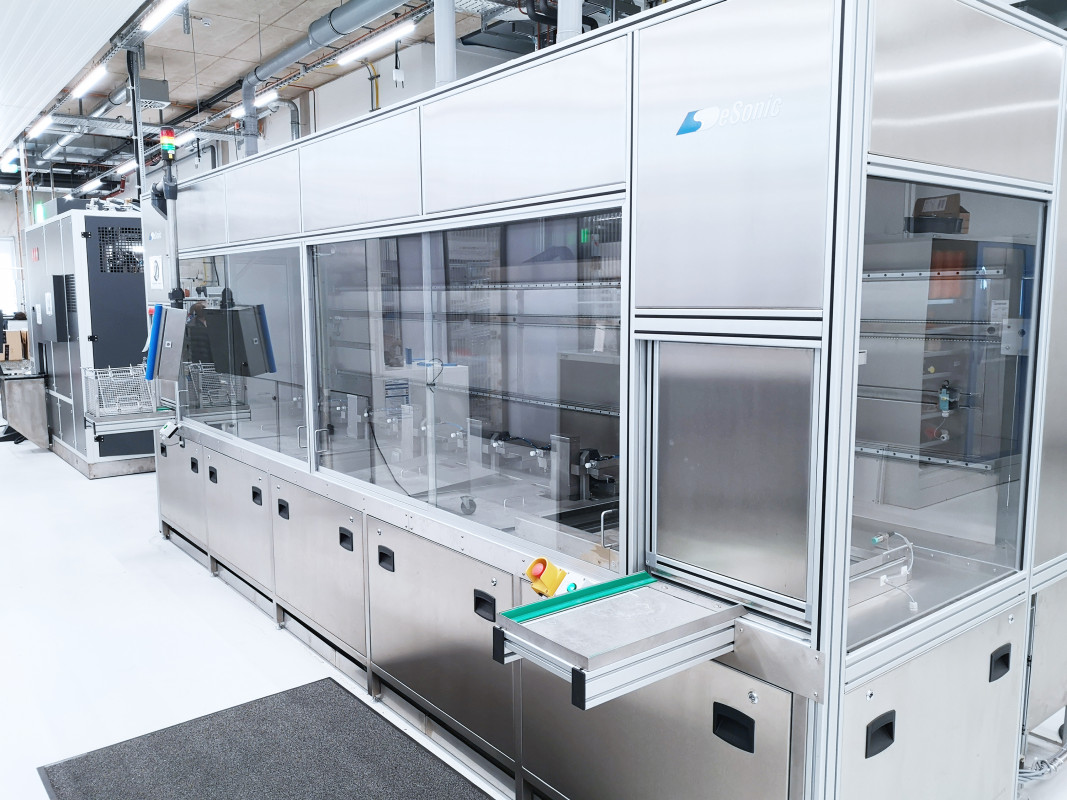

At the Fraunhofer FEP, the existing cleaning technology has been expanded to include a multi-chamber cleaning system for aqueous ultrasonic cleaning as part of the LinTR project. The pilot-scale system has a capacity of 100 litres per basin and, unlike many conventional ultrasonic cleaning systems, has very flexibly controllable parameter sets.

Project manager Daniel Weile explains the advantages: ‘The system does not have any rigid ultrasonic systems installed, but instead allows individual ultrasonic generators to be controlled. This means that the direction, frequency and power of the ultrasound, and thus also the cleaning effect, can be varied over a wide range. This means that the cleaning processes can be precisely adjusted to a wide range of contaminants and components. The sequence of cleaning processes in the six tanks can also be freely adjusted via an automatic system.’

This wide range of variations is to be used in the future as part of the LinTR learning laboratory. In order to use the theoretical content of the training courses in an effective didactic way, various cleaning processes and test methods are applied in practice. To this end, a special two-part test component has been developed that contains typical geometries and materials of industrial components, such as a wide range of boreholes, edges and screw connections, as well as material combinations of metal, plastic and additively manufactured components.

‘One of the practical tasks within LinTR for the participants is to optimise the parameters for cleaning this standard component. Our multi-chamber system is perfect for this. The flexibility of the individual control variables of the system allows the participants to practice and optimise the cleaning processes until the impurities on the test component are removed with the optimal setting,’ continues Weile.

The cleaning task consists of a defined model contamination on the standard component. For this purpose, production-relevant, typical contaminants (lubricating oil, cooling lubricant and grinding paste) are applied to the component in a standardised manner and then processed using various methods. In the training course, participants have the opportunity to find a satisfactory solution to the cleaning task by varying the process parameters. The standardised starting conditions then enable a comparative analysis of the different processes and show the limits and possibilities of the methods using a practical example. A final analysis of the components is also an integral part of the practical work.

The multi-chamber cleaning system will be put into operation by the time the LinTR learning laboratory project is completed in September 2024 and should be available for the first practical cleaning processes at the end of the year. In addition, from autumn 2024, the four project partners of the learning laboratory will have a complete modular system for training in industrial component cleaning, which is precisely tailored to the requirements of manufacturing companies and offers practical training units at existing laboratories for the first time.

The Fraunhofer FEP will be providing information about all the possibilities offered by the LinTR learning laboratory, the further training programme to become a ‘Certified Specialist (m/f/d) for Industrial Parts Cleaning’ and other topics related to research in industrial parts cleaning at the 32nd Industrial Parts Cleaning Conference in Dresden from 11–12 September 2024, in the exhibition accompanying the conference.