Manual grinding is a labor-intensive process that tends to be unpopular. With a machine specially developed for foundries, the DISA Group can now automate this process.

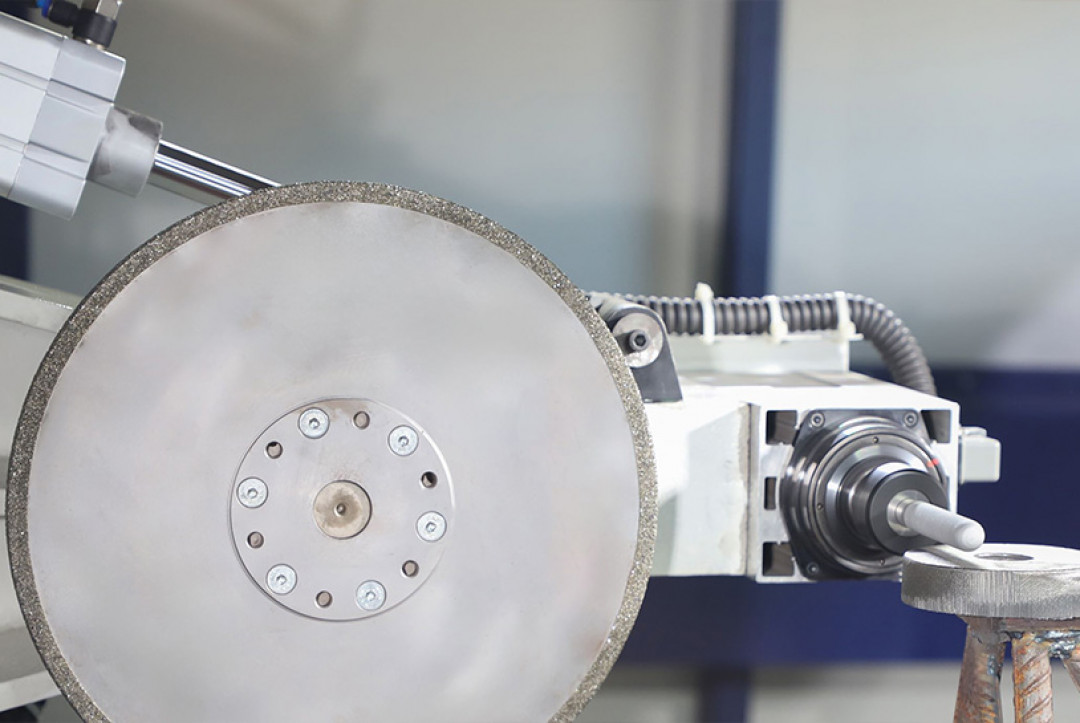

DISA Group has launched "DISA Grind", an automated grinding solution specifically designed for foundries. It can finish all alloys, from iron and aluminum to steel, bronze, and copper.

“Manual grinding is slow, inconsistent, dirty and dangerous. It’s no surprise that foundries struggle to find workers who want to do this job,” says Kasper Paw Madsen, Vice President Portfolio Development & Marketing at DISA. “Automated grinding with DISA Grind removes this labor-intensive bottleneck, boosting productivity and quality, plus it makes your foundry a much safer, cleaner and more appealing place to work.”

Easy-to-use auto grinding

Unlike conventional auto grinding equipment, DISA Grind does not require CNC programming skills. Anyone can quickly learn to program it using its intuitive touchscreen and handheld control box.

“Adjust the dial to accurately position the grinding tool, then simply press the blue button to record its location,” explains Kasper. “It’s ideal for foundries that handle short runs with frequent new castings. You need far fewer operators, there’s almost no training required, and the work is cleaner and safer, so you can recruit more easily and retain staff longer too.”

Available in two sizes, DISA Grind can grind castings up to 1200 kg (2,645 lbs). The T-750 handles castings up to 940 mm (37 in) diameter x 400 mm (15.75 in) height and the T-1250 grinds workpieces up to 1340 mm (52.75 in) diameter x 750 mm (29.5 in) height.

Featured photo: DISA Group