Chongyang Zeng from the Chair of Lightweight Vehicle Construction at the University of Siegen has further developed a method for measuring the behaviour of materials under crash loads. He has been awarded first place in the international research prize "ZwickRoell Science Award" for this.

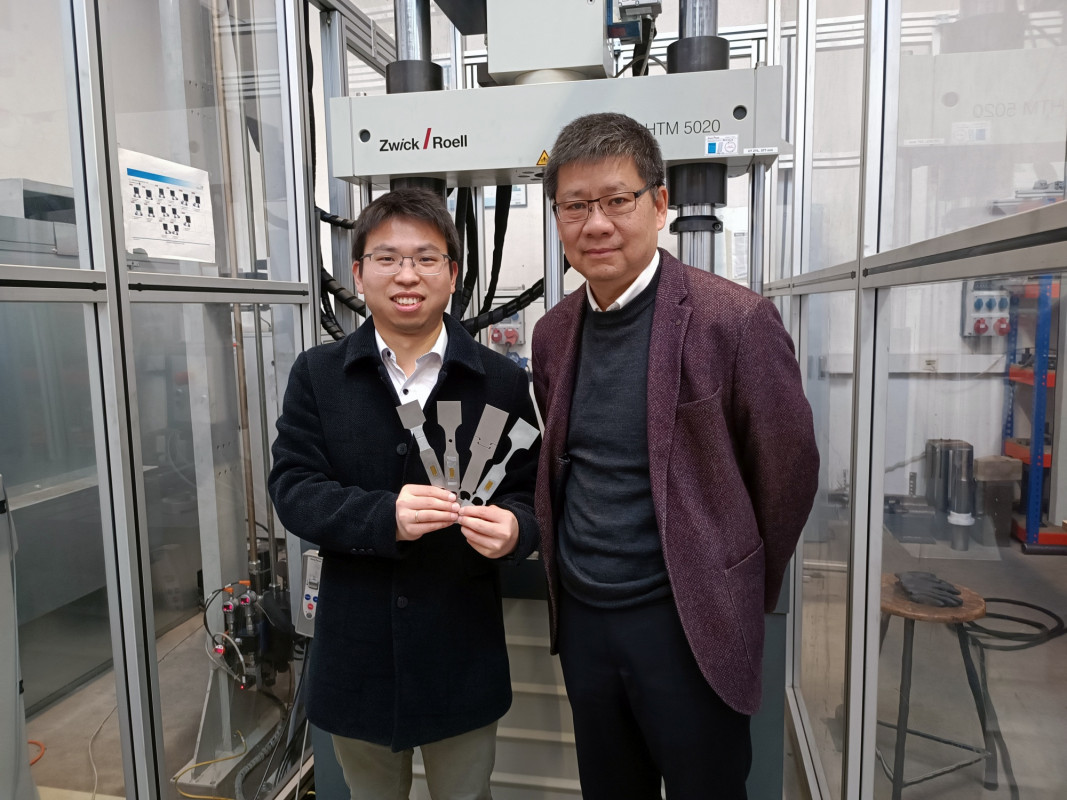

In the event of a car accident, the vehicle occupants rely on the car body withstanding the impact of the collision as well as possible. To achieve this, the material for the components is intensively tested in advance. The problem: vibrations occur, especially in high-speed crashes, which make precise force measurements difficult. Vehicle engineers at the University of Siegen have developed a solution to this problem: they shape the material samples for their measurements into a special geometric form – the energies during the test are thus redistributed in such a way that no more disruptive vibrations occur and exact results are achieved. Chongyang Zeng from the Chair of Lightweight Vehicle Construction has now further developed this already patented process. The young scientist has been awarded first place in the international research prize "ZwickRoell Science Award" for his work.

"I am delighted to receive this award, for which more than 160 scientists from over 35 countries applied. To be selected from so many applications for first place is a great surprise and at the same time recognition for the research at our chair," says Chongyang Zeng, who previously completed his master's degree in metallurgy at RWTH Aachen University.

The study for which he has now been honoured is part of his doctoral thesis as part of a research project by the German Research Foundation (DFG) on crash simulations. Zeng has developed further geometric test moulds with different stress states that enable precise force measurements. In addition, he has discovered new laws and implemented them in a physical process for vibration-free force measurement. "With this enhanced measurement method, we can now predict even more accurately whether various types of steel that are being considered for the production of body components will withstand the stress of a crash," explains Prof. Dr.-Ing. Xiangfan Fang, who holds the chair at the University of Siegen.

In lightweight vehicle construction, such precise measurement methods are of particular importance: in order to build the lightest possible vehicles, it is necessary to determine exactly how far the material thickness of the components can be reduced without the material losing its strength. The DFG project, in which scientists from the University of Siegen are working together with colleagues from RWTH Aachen University, will run for another year. During this time, the researchers will work on making the advanced measurement methods actually applicable in practice.

The ZwickRoell Science Award is presented annually to researchers who have produced outstanding scientific work in the field of mechanical materials testing. The first prize is worth 5,000 euros, and Chongyang Zeng will also receive the Paul Roell Medal for his achievement. The award ceremony will take place in October in Ulm.