SMEs face the challenge of integrating innovative technologies such as 3D printing into their production processes in a cost-efficient way. The BAM showroom offers a platform to demonstrate how additive manufacturing can be incorporated into existing processes while taking digital quality assurance into account.

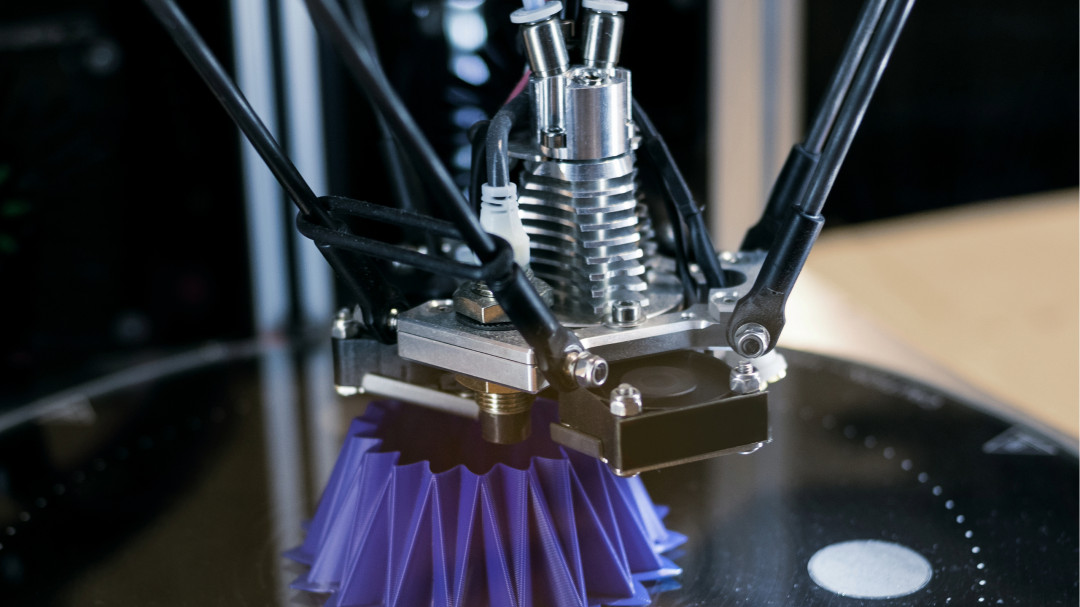

At interactive stations, visitors can experience the individual phases of the 3D printing process up close – from powder to finished component. For example, the flow behaviour of different powders can be observed. Visitors can assemble a wall model from differently shaped plastic building blocks that illustrates the use of additive manufacturing processes in functionally integrated building construction.

One focus of the showroom is on 3D-printed components made of concrete, metal and ceramic that cannot be manufactured using conventional production methods. One example of this is a turbine blade with complex structures that improves the efficiency of modern turbines. A heat exchanger developed using algorithms from the software company Hyperganic also shows how advanced design approaches can not only enable production but also optimise product performance.

Another highlight is the so-called ‘data treasure’. This exhibit demonstrates the enormous amounts of data that are generated during additive manufacturing and subsequent quality assurance. It shows how SMEs can use this previously untapped potential to further develop digital quality assurance procedures and optimise their production processes.

BAM President Prof. Dr. Ulrich Panne explains at the opening: ‘Our additive manufacturing showroom offers SMEs a unique opportunity to discover the latest technologies, evaluate them for their production and develop new ideas in cooperation with BAM. The interactive exhibits make the complex technological processes tangible and understandable.’